Particularly striking features are the chequer-board effect on the counter and the herringbone design on the door, adding to the vibrant, eclectic feel of the interior:

English tile manufacturers based in Stoke-on-Trent since 1926. Visit www.hesmith.co.uk for our full website.

Monday 25 November 2013

Jamie's Italian, Canberra

Tiles we manufactured for Jamie's Italian in Canberra, Australia are now in place and looking great.

Monday 4 November 2013

Case study: Giraffe, Bath

The Giraffe restaurant in Bath is "inspired by New York’s clubby coffee shops and restaurants", so what better tile to use in the décor than H&E Smith's bevelled Metro.

In the bar area, classic white tiles, reminiscent of NYC's subway, were coupled with stripes of sunshine yellow reflecting the Giraffe brand's bright and fun personality. Porcelain floor tiles in more subtle tones of grey and yellow created a distinguished, chequer-board bar zone, complimenting the wall tiles.

The result was a stunning, central bar area at the heart of the restaurant.

In the bar area, classic white tiles, reminiscent of NYC's subway, were coupled with stripes of sunshine yellow reflecting the Giraffe brand's bright and fun personality. Porcelain floor tiles in more subtle tones of grey and yellow created a distinguished, chequer-board bar zone, complimenting the wall tiles.

The result was a stunning, central bar area at the heart of the restaurant.

6x3" Metro wall tiles in Polished White and Inca Gold made by H&E Smith Ltd

"Chequers" porcelain floor tiles in Light Grey and Yellow Ochre supplied by H&E Smith Ltd

Monday 30 September 2013

H&E Smith Ltd: Turning the corner

One of H&E Smith’s greatest assets is our capability to design and manufacture solid-ceramic corner tiles.

We can create corner tiles in a variety of sizes, shapes and formats, resulting in a high-quality, seamless finish to installations. This versatility has proved invaluable in numerous projects we have completed, and has enabled us to provide our clients with design solutions that are both technically and aesthetically sound.

Below is just a small selection of the corner tiles we produce:

We can create corner tiles in a variety of sizes, shapes and formats, resulting in a high-quality, seamless finish to installations. This versatility has proved invaluable in numerous projects we have completed, and has enabled us to provide our clients with design solutions that are both technically and aesthetically sound.

Below is just a small selection of the corner tiles we produce:

Above right: 4.5x3" external quadrant corners shown in Teapot Brown & Snowdrop,

as used in the Ben Sherman Carnaby Street store (left)

Above: Coved skirting corner tiles in Pure White,

as produced for Hawksmoor Restaurant, Spitalfields, London

Above, left to right:

Corner for 6x2"quadrant tile in Victorian Black;

45 degree skirting corner in Victorian Green (for use with 4.5x3" quadrant corner); cornice corner in Jade.

Corner for 6x2"quadrant tile in Victorian Black;

45 degree skirting corner in Victorian Green (for use with 4.5x3" quadrant corner); cornice corner in Jade.

Friday 6 September 2013

Flying the flag: our tiled Union Jack

A great project we've been working on here at H&E Smith Ltd has recently gone from a work-in-progress in our factory...

...to a bold, impactful statement piece. The Union Jack was created from individual tiles, painstakingly cut and positioned by hand to form the lines of the flag. The tiles were glazed in Midnight Blue, Burgundy and Snowdrop, and the high-shine finish really shows off the colours.

Since creating this flag, we've been commissioned by a customer to make a bespoke Union Jack in varying shades of pink! Watch this space for photos of the finished piece...

Since creating this flag, we've been commissioned by a customer to make a bespoke Union Jack in varying shades of pink! Watch this space for photos of the finished piece...

Great British tiles!

Wednesday 4 September 2013

Crackle tiles

If you're looking for tiles with some subtle detailing, H&E Smith's crackle glaze may be just for you.

Our crackle tiles are distinctive but not overpowering. The finish gives them a wonderful antique, aged feel which would really compliment a vintage or shabby chic style setting.

The tiles are available in a range of sizes and formats - please get in touch for more information.

Our crackle tiles are distinctive but not overpowering. The finish gives them a wonderful antique, aged feel which would really compliment a vintage or shabby chic style setting.

The tiles are available in a range of sizes and formats - please get in touch for more information.

Tuesday 3 September 2013

New British Ceramic Tile ranges in showroom

We have some beautiful new ranges from British Ceramic Tile in our showroom, perfect if you're thinking of redecorating as we move towards Autumn and Winter.

Whether you want a modern, contemporary tile or something more traditional, the range spans a variety of styles and genres - there is something for everyone. A small selection of the new tiles is shown below to give you a taster of what's on offer; however nothing compares to visiting our showroom and seeing the tiles in their full glory.

Whether you want a modern, contemporary tile or something more traditional, the range spans a variety of styles and genres - there is something for everyone. A small selection of the new tiles is shown below to give you a taster of what's on offer; however nothing compares to visiting our showroom and seeing the tiles in their full glory.

Above Left: Rapolano Noce / Right: Marmaris Noce

Above: Ditto Wave Light Grey

Above left: Mimeo Grey / Right: Murmur Grey

Images courtesy of British Ceramic Tile

Images courtesy of British Ceramic Tile

Monday 2 September 2013

Get ready for winter!

We don't want to wish summer away any faster, but now it's September thoughts of the colder months will no doubt start creeping into our minds...

With log burners and wood burning stoves extremely popular at the moment, you may be considering investing in one to ensure your home stays warm and cosy this winter. If so, H&E Smith Ltd offer a wide range of tiles suitable for hearths and areas housing a burner or stove.

From our traditional Basalt Black tile to the more colourful, glazed tiles produced at our Stoke-on-Trent factory, we're certain you'll find something to suit your requirements.

You can find tiles suitable for fireplaces and burners here, along with heat-proof adhesive for their installation. As well as standard plain tiles, we provide round-edge and double round-edge tiles for use on edges and corners of hearths if needed.

Keep cosy this winter!

With log burners and wood burning stoves extremely popular at the moment, you may be considering investing in one to ensure your home stays warm and cosy this winter. If so, H&E Smith Ltd offer a wide range of tiles suitable for hearths and areas housing a burner or stove.

From our traditional Basalt Black tile to the more colourful, glazed tiles produced at our Stoke-on-Trent factory, we're certain you'll find something to suit your requirements.

Above: Victorian Green & Victorian Blue glazed fireplace tiles

We also provide beautiful, earth-tone quarry tiles - perfect for when you want something a little more rustic or neutral so that your log burner takes pride of place.

You can find tiles suitable for fireplaces and burners here, along with heat-proof adhesive for their installation. As well as standard plain tiles, we provide round-edge and double round-edge tiles for use on edges and corners of hearths if needed.

Keep cosy this winter!

Thursday 18 July 2013

H&E Smith in the press

We were featured in a great article this month - "Going underground" by Melanie Rutherford of Clay Technology. All about our work for the London Underground, the article discusses our manufacturing processes and why we've had success in this area, along with our plans for the future.

Read the full article below - with thanks to Melanie and Clay Technology/ICTa.

As the London Underground celebrates its 150th anniversary, Melanie Rutherford speaks to Fred Smith from H&E Smith Ltd, a family-run bespoke tile company based in Staffordshire, UK, which has been supplying tiles to maintain tube stations’ historical features for more than 25 years.

Join the millions of passengers pouring into London Underground’s 270 tube stations and chances are you won’t pay a second glance to the tile-clad walls. But it’s worth taking a closer look. Get close enough and you might just be able to spot a brand new tile sitting among its much older neighbours.

With heritage an intrinsic part of the world’s oldest underground transport network, maintenance of the existing tilework – from replacing a lone tile to complete regeneration – is key to conserving its history. That means sourcing tiles that exactly replicate the colours and finishes produced when the stations were first built – not an easy task. Bespoke tile manufacturer H&E Smith is one company whose traditional manufacturing methods have been helping London Underground do just that.

With heritage an intrinsic part of the world’s oldest underground transport network, maintenance of the existing tilework – from replacing a lone tile to complete regeneration – is key to conserving its history. That means sourcing tiles that exactly replicate the colours and finishes produced when the stations were first built – not an easy task. Bespoke tile manufacturer H&E Smith is one company whose traditional manufacturing methods have been helping London Underground do just that.

Fred Smith, the third generation of the family to be involved in the Staffordshire-based company, explains, ‘We started working with London Underground in 1988, just after I joined the company in 1986. We received an enquiry asking if we could make tiles to match existing ones at the heritage stations. We could, and so we got the job. Fundamentally, it was because of our manufacturing technique.’ While modern tile manufacturers have shifted towards fast-fire methods more suited to mass-production, H&E Smith has continued to work with the more traditional twice-fired method. Smith continues, ‘This allows us to create the glaze effects that were produced when making the tiles that were used on the London Underground 100 years ago.’

The company’s manufacturing method has played a key role in the conservation of tube stations including Arsenal, Bond Street, Camden Town, Covent Garden, Knightsbridge and Maida Vale – 23 in total. Twice-firing is a traditional way of making tiles with traditional types of body. The first step in the process is firing the biscuit – the unglazed tile substrate – from pressed clay dust. This is done on a long, slow firing with plenty of soak, to around 1,100°C. ‘After the biscuit has been cooled and selected, and has passed the first quality test, we send it down a dipping line where the glaze is applied,’ explains Smith. ‘The tile is put into a crank – a piece of kiln furniture that holds the tile so that the glaze doesn’t run and touch the sides of the kiln or any of the other tiles – before being re-fired at the glaze stage to just over 1,000°C, on a shorter firing.’ Once cooled for a second time, the tile is then checked for quality and boxed.

Sounds simple. Why, then, are more companies not manufacturing tiles in this way? ‘The main challenge of this method of production is raw material supply,’ explains Smith. Twice-firing requires materials that are not always widely available – including stains, oxides, frits, clay bodies and their constituent parts, and equipment to refine the body, which has to be in a spray-dry format. ‘Procurement of raw materials is always a difficulty,’ says Smith. ‘When they are no longer available we have to make adjustments and work with other materials.’

Sounds simple. Why, then, are more companies not manufacturing tiles in this way? ‘The main challenge of this method of production is raw material supply,’ explains Smith. Twice-firing requires materials that are not always widely available – including stains, oxides, frits, clay bodies and their constituent parts, and equipment to refine the body, which has to be in a spray-dry format. ‘Procurement of raw materials is always a difficulty,’ says Smith. ‘When they are no longer available we have to make adjustments and work with other materials.’

A significant challenge specific to the production of tiles for the London Underground is that of colour matching, especially when it comes to patch and repair. Matching new tiles to those that may have been in a tube station for several decades can take a long time, not least because it means working with different materials to those that achieved the original colour effect. Smith explains, ‘Most of the original tiles would have been made using leaded glazes, because at that time there was no control over the lead content in the glaze. But in 1924, factories outlawed the use of raw lead in glaze, so now we have to use lead in fritted form.’

Adding to the problem is the use of modern-day electric kilns compared to the coal-fired bottle kilns that would have been used to fire the original tiles for the London Underground. ‘Electric kilns tend to fire far cleaner than the old coal-fired bottle kilns, so you get different colour results,’ Smith explains. ‘And there are other challenges in the form of the substrate – the clay underneath the tile could have been different, and that sometimes has a bearing on the overall effect.’

For the majority of the heavy clay industry, advances in technology have revolutionised manufacture, but for companies such as H&E Smith, which does things in the traditional way, the new technology has had very little impact on production. While Smith admits that advances have helped the business in terms of administration, computerisation and data capture, ‘when it comes to the actual manufacturing methods there’s very little really, except maybe firing control’.

Keeping it in the family

With a history almost as long as the Underground itself, H&E Smith has kept it in the family. The company was founded by Smith’s grandfather, William Henry Smith, and his business partner William Warrilow, in 1926 when it traded under the name of Smith &Warrilow. The company was set up for the fireplace tile industry – ‘a healthy market at the time,’ says Smith. When Warrilow retired in 1947, Smith’s father joined the company and so H&E Smith Ltd was born.

Since it first started supplying tiles for the London Underground in 1988, Smith predicts his company has produced more than one million tiles for the network. ‘We have done an average of about 1,000 metres a year with them, so over 25 years that’s 25,000 metres. At 56 tiles per metre that’s 1.5 million tiles over that period.’ Though Smith adds that the work comes in fits and starts, with times when the company doesn’t get any commissions from the London Underground at all. ‘We found that we had a period of regular business from 2003–2009, then in the build-up to the Olympics everything closed down,’ says Smith. ‘But now that they are starting to continue their re-servicing programme, work is trickling back in.’

Since it first started supplying tiles for the London Underground in 1988, Smith predicts his company has produced more than one million tiles for the network. ‘We have done an average of about 1,000 metres a year with them, so over 25 years that’s 25,000 metres. At 56 tiles per metre that’s 1.5 million tiles over that period.’ Though Smith adds that the work comes in fits and starts, with times when the company doesn’t get any commissions from the London Underground at all. ‘We found that we had a period of regular business from 2003–2009, then in the build-up to the Olympics everything closed down,’ says Smith. ‘But now that they are starting to continue their re-servicing programme, work is trickling back in.’

While many companies expand over time, H&E Smith has bucked the trend, contracting in staff numbers since his Smith’s grandfather co-founded the business more than 85 years ago. ‘With the increase in wage costs and the decline in the market for fireplace tiles, we’ve had to alter our company accordingly,’ says Smith. ‘Now the business is relatively small, employing about 30 people. We see ourselves as a bespoke tile manufacturer, supplying to interior designers and clients who want to have something completely different.’ The client list includes some high-profile names, with recently completed projects including Harrods (for Christian Louboutin) and continued work for the Ben Sherman Group and restaurant chains such as Jamie Oliver’s, Nando’s and Zizzi.

This small snapshot alone is proof that demand is still out there for bespoke tile manufacture – and Smith doesn’t see that changing any time soon. ‘We continue to do it because we’re market-led,’ he says. ‘We don’t see the need to try and do what everybody else is doing. When it comes to volume tiling, we tend to source that tile from other people, such as British Ceramic Tile in the south west of England. There is no point in us getting involved in that particular market – you need a lot more space and you need to be a far bigger operation to make it viable.’

Back to the future

While H&E Smith’s production methods have changed very little over the last 85 years, the company is fully aware of environmental issues, and is working to increase production efficiency and looking at opportunities for recycling. ‘We take our responsibilities very seriously,’ says Smith. ‘We look to every opportunity for saving energy, and that is vital now energy prices are so high. We have become far more efficient over the last 10 years – we do not manufacture in old, inefficient tunnel kilns any longer and now use more modern, intermittent kilns that allow us to control our volume of production.’

While H&E Smith’s production methods have changed very little over the last 85 years, the company is fully aware of environmental issues, and is working to increase production efficiency and looking at opportunities for recycling. ‘We take our responsibilities very seriously,’ says Smith. ‘We look to every opportunity for saving energy, and that is vital now energy prices are so high. We have become far more efficient over the last 10 years – we do not manufacture in old, inefficient tunnel kilns any longer and now use more modern, intermittent kilns that allow us to control our volume of production.’

Then there are the vagaries of the UK economic climate to contend with. ‘As the economy has grown, as everything has gone up in price and costs have increased, at times it has been difficult to make our part of the job viable,’ says Smith. The solution? ‘It means that we have to go upstream and choose to make far more expensive products. There’s no other way.’ Will London Underground still be relying on the company’s age-old manufacturing method for its unique, historical tiles another 150 years from now? Here’s hoping so.

By Melanie Rutherford

This article appeared in the June/July 2013 issue of Clay Technology, the magazine of ICTa – an association within the Ceramics Society, a division of the Institute of Materials, Minerals and Mining (IOM3).

Clay Technology is a bi-monthly magazine focusing on clay products such as tiles, pipes and bricks, innovative use of heavy clay products, and people within the industry. The magazine includes features, news from the industry, economic updates and event previews. If you are interested in becoming a member of ICTa or subscribing to Clay Technology magazine, click here.

Read the full article below - with thanks to Melanie and Clay Technology/ICTa.

* * * * * * * * * *

Going undergroundAs the London Underground celebrates its 150th anniversary, Melanie Rutherford speaks to Fred Smith from H&E Smith Ltd, a family-run bespoke tile company based in Staffordshire, UK, which has been supplying tiles to maintain tube stations’ historical features for more than 25 years.

Join the millions of passengers pouring into London Underground’s 270 tube stations and chances are you won’t pay a second glance to the tile-clad walls. But it’s worth taking a closer look. Get close enough and you might just be able to spot a brand new tile sitting among its much older neighbours.

With heritage an intrinsic part of the world’s oldest underground transport network, maintenance of the existing tilework – from replacing a lone tile to complete regeneration – is key to conserving its history. That means sourcing tiles that exactly replicate the colours and finishes produced when the stations were first built – not an easy task. Bespoke tile manufacturer H&E Smith is one company whose traditional manufacturing methods have been helping London Underground do just that.

With heritage an intrinsic part of the world’s oldest underground transport network, maintenance of the existing tilework – from replacing a lone tile to complete regeneration – is key to conserving its history. That means sourcing tiles that exactly replicate the colours and finishes produced when the stations were first built – not an easy task. Bespoke tile manufacturer H&E Smith is one company whose traditional manufacturing methods have been helping London Underground do just that.Fred Smith, the third generation of the family to be involved in the Staffordshire-based company, explains, ‘We started working with London Underground in 1988, just after I joined the company in 1986. We received an enquiry asking if we could make tiles to match existing ones at the heritage stations. We could, and so we got the job. Fundamentally, it was because of our manufacturing technique.’ While modern tile manufacturers have shifted towards fast-fire methods more suited to mass-production, H&E Smith has continued to work with the more traditional twice-fired method. Smith continues, ‘This allows us to create the glaze effects that were produced when making the tiles that were used on the London Underground 100 years ago.’

The company’s manufacturing method has played a key role in the conservation of tube stations including Arsenal, Bond Street, Camden Town, Covent Garden, Knightsbridge and Maida Vale – 23 in total. Twice-firing is a traditional way of making tiles with traditional types of body. The first step in the process is firing the biscuit – the unglazed tile substrate – from pressed clay dust. This is done on a long, slow firing with plenty of soak, to around 1,100°C. ‘After the biscuit has been cooled and selected, and has passed the first quality test, we send it down a dipping line where the glaze is applied,’ explains Smith. ‘The tile is put into a crank – a piece of kiln furniture that holds the tile so that the glaze doesn’t run and touch the sides of the kiln or any of the other tiles – before being re-fired at the glaze stage to just over 1,000°C, on a shorter firing.’ Once cooled for a second time, the tile is then checked for quality and boxed.

Sounds simple. Why, then, are more companies not manufacturing tiles in this way? ‘The main challenge of this method of production is raw material supply,’ explains Smith. Twice-firing requires materials that are not always widely available – including stains, oxides, frits, clay bodies and their constituent parts, and equipment to refine the body, which has to be in a spray-dry format. ‘Procurement of raw materials is always a difficulty,’ says Smith. ‘When they are no longer available we have to make adjustments and work with other materials.’

Sounds simple. Why, then, are more companies not manufacturing tiles in this way? ‘The main challenge of this method of production is raw material supply,’ explains Smith. Twice-firing requires materials that are not always widely available – including stains, oxides, frits, clay bodies and their constituent parts, and equipment to refine the body, which has to be in a spray-dry format. ‘Procurement of raw materials is always a difficulty,’ says Smith. ‘When they are no longer available we have to make adjustments and work with other materials.’A significant challenge specific to the production of tiles for the London Underground is that of colour matching, especially when it comes to patch and repair. Matching new tiles to those that may have been in a tube station for several decades can take a long time, not least because it means working with different materials to those that achieved the original colour effect. Smith explains, ‘Most of the original tiles would have been made using leaded glazes, because at that time there was no control over the lead content in the glaze. But in 1924, factories outlawed the use of raw lead in glaze, so now we have to use lead in fritted form.’

Adding to the problem is the use of modern-day electric kilns compared to the coal-fired bottle kilns that would have been used to fire the original tiles for the London Underground. ‘Electric kilns tend to fire far cleaner than the old coal-fired bottle kilns, so you get different colour results,’ Smith explains. ‘And there are other challenges in the form of the substrate – the clay underneath the tile could have been different, and that sometimes has a bearing on the overall effect.’

For the majority of the heavy clay industry, advances in technology have revolutionised manufacture, but for companies such as H&E Smith, which does things in the traditional way, the new technology has had very little impact on production. While Smith admits that advances have helped the business in terms of administration, computerisation and data capture, ‘when it comes to the actual manufacturing methods there’s very little really, except maybe firing control’.

Keeping it in the family

With a history almost as long as the Underground itself, H&E Smith has kept it in the family. The company was founded by Smith’s grandfather, William Henry Smith, and his business partner William Warrilow, in 1926 when it traded under the name of Smith &Warrilow. The company was set up for the fireplace tile industry – ‘a healthy market at the time,’ says Smith. When Warrilow retired in 1947, Smith’s father joined the company and so H&E Smith Ltd was born.

Since it first started supplying tiles for the London Underground in 1988, Smith predicts his company has produced more than one million tiles for the network. ‘We have done an average of about 1,000 metres a year with them, so over 25 years that’s 25,000 metres. At 56 tiles per metre that’s 1.5 million tiles over that period.’ Though Smith adds that the work comes in fits and starts, with times when the company doesn’t get any commissions from the London Underground at all. ‘We found that we had a period of regular business from 2003–2009, then in the build-up to the Olympics everything closed down,’ says Smith. ‘But now that they are starting to continue their re-servicing programme, work is trickling back in.’

Since it first started supplying tiles for the London Underground in 1988, Smith predicts his company has produced more than one million tiles for the network. ‘We have done an average of about 1,000 metres a year with them, so over 25 years that’s 25,000 metres. At 56 tiles per metre that’s 1.5 million tiles over that period.’ Though Smith adds that the work comes in fits and starts, with times when the company doesn’t get any commissions from the London Underground at all. ‘We found that we had a period of regular business from 2003–2009, then in the build-up to the Olympics everything closed down,’ says Smith. ‘But now that they are starting to continue their re-servicing programme, work is trickling back in.’While many companies expand over time, H&E Smith has bucked the trend, contracting in staff numbers since his Smith’s grandfather co-founded the business more than 85 years ago. ‘With the increase in wage costs and the decline in the market for fireplace tiles, we’ve had to alter our company accordingly,’ says Smith. ‘Now the business is relatively small, employing about 30 people. We see ourselves as a bespoke tile manufacturer, supplying to interior designers and clients who want to have something completely different.’ The client list includes some high-profile names, with recently completed projects including Harrods (for Christian Louboutin) and continued work for the Ben Sherman Group and restaurant chains such as Jamie Oliver’s, Nando’s and Zizzi.

This small snapshot alone is proof that demand is still out there for bespoke tile manufacture – and Smith doesn’t see that changing any time soon. ‘We continue to do it because we’re market-led,’ he says. ‘We don’t see the need to try and do what everybody else is doing. When it comes to volume tiling, we tend to source that tile from other people, such as British Ceramic Tile in the south west of England. There is no point in us getting involved in that particular market – you need a lot more space and you need to be a far bigger operation to make it viable.’

Back to the future

While H&E Smith’s production methods have changed very little over the last 85 years, the company is fully aware of environmental issues, and is working to increase production efficiency and looking at opportunities for recycling. ‘We take our responsibilities very seriously,’ says Smith. ‘We look to every opportunity for saving energy, and that is vital now energy prices are so high. We have become far more efficient over the last 10 years – we do not manufacture in old, inefficient tunnel kilns any longer and now use more modern, intermittent kilns that allow us to control our volume of production.’

While H&E Smith’s production methods have changed very little over the last 85 years, the company is fully aware of environmental issues, and is working to increase production efficiency and looking at opportunities for recycling. ‘We take our responsibilities very seriously,’ says Smith. ‘We look to every opportunity for saving energy, and that is vital now energy prices are so high. We have become far more efficient over the last 10 years – we do not manufacture in old, inefficient tunnel kilns any longer and now use more modern, intermittent kilns that allow us to control our volume of production.’Then there are the vagaries of the UK economic climate to contend with. ‘As the economy has grown, as everything has gone up in price and costs have increased, at times it has been difficult to make our part of the job viable,’ says Smith. The solution? ‘It means that we have to go upstream and choose to make far more expensive products. There’s no other way.’ Will London Underground still be relying on the company’s age-old manufacturing method for its unique, historical tiles another 150 years from now? Here’s hoping so.

By Melanie Rutherford

This article appeared in the June/July 2013 issue of Clay Technology, the magazine of ICTa – an association within the Ceramics Society, a division of the Institute of Materials, Minerals and Mining (IOM3).

Clay Technology is a bi-monthly magazine focusing on clay products such as tiles, pipes and bricks, innovative use of heavy clay products, and people within the industry. The magazine includes features, news from the industry, economic updates and event previews. If you are interested in becoming a member of ICTa or subscribing to Clay Technology magazine, click here.

Friday 12 July 2013

New showroom boards

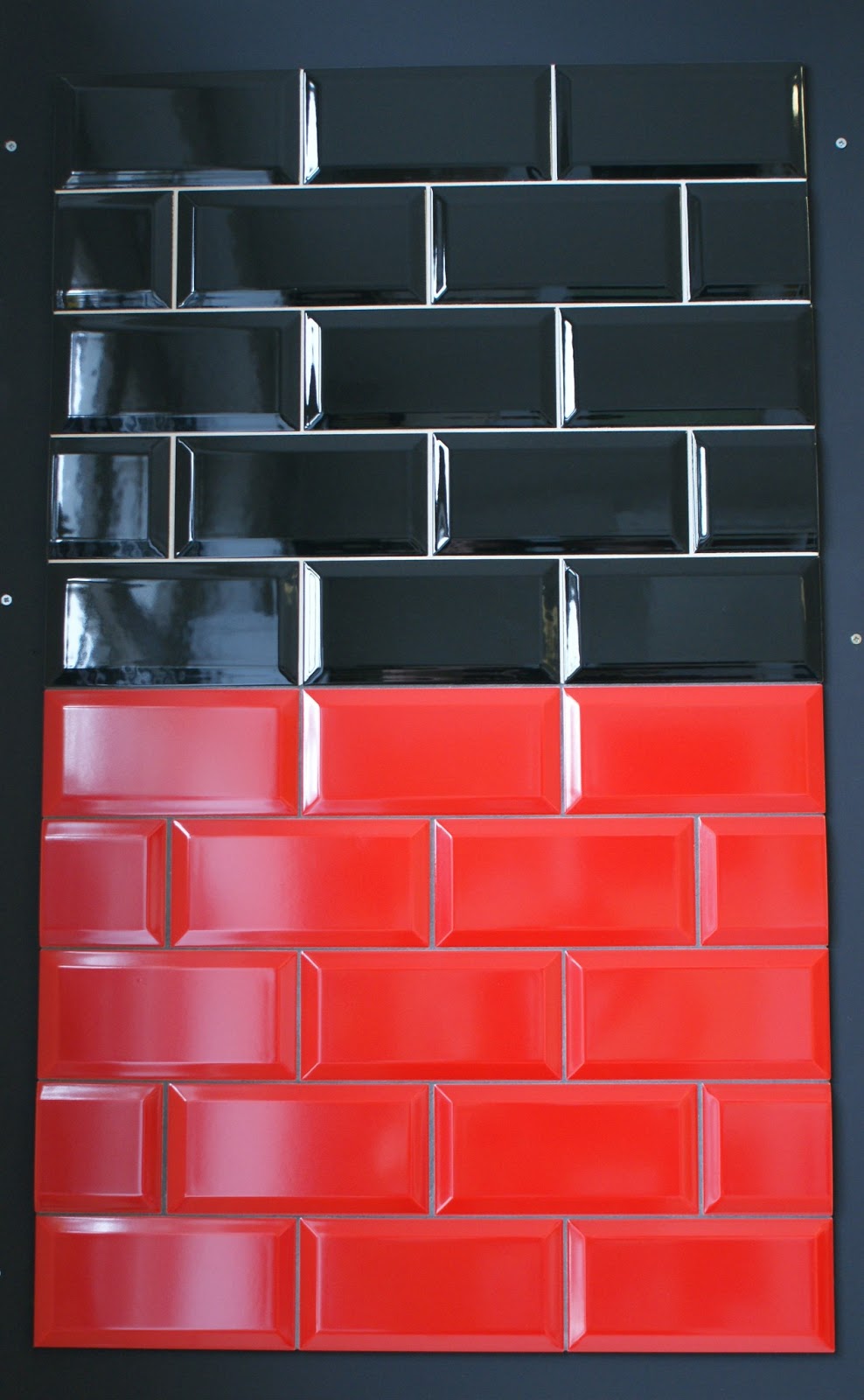

We've had some gorgeous new boards put up in the H&E Smith Ltd showroom, which really showcase how the different mouldings and colours we produce can work together.

The images above show combinations of our Metro and Period Embossed ranges, and demonstrate how different looks can be achieved to suit different surroundings - both classical and more contemporary.

Pop in and see what else we have to offer:

H&E Smith Ltd, Broom Street, Hanley, Stoke-on-Trent, ST1 2ER

Sunshine Friday

A beautiful, bright, bespoke tile to match the current summer weather!

This is the bespoke Dimple tile we created for Nando's in Halifax. The vibrant mustard colour is very impactful and makes a real statement, perfect for the Nando's style and ethos.

Tuesday 25 June 2013

Porcelain tile sale at FireTile

H&E Smith's sister company, FireTile, have a porcelain tile sale online.

Up to 50% off, however limited stock so don't miss out!

Visit: http://www.firetile.co.uk/acatalog/Clearance-and-Sale-Items.html

Up to 50% off, however limited stock so don't miss out!

Visit: http://www.firetile.co.uk/acatalog/Clearance-and-Sale-Items.html

Friday 21 June 2013

Reproduction tiles & restorations

H&E Smith have a great deal of experience in producing tiles for restoration projects, most notably for the vast and ongoing refurbishment of the London Underground.

Using a combination of cutting-edge technology and more traditional methods, we have the capability to match and recreate tiles, replicating designs, colours and finishes perfectly. We have been involved with several projects overseen by the English Heritage, where exceptional accuracy and quality have been paramount.

Below are some "before and after" examples of reproduction tiles we have created:

Using a combination of cutting-edge technology and more traditional methods, we have the capability to match and recreate tiles, replicating designs, colours and finishes perfectly. We have been involved with several projects overseen by the English Heritage, where exceptional accuracy and quality have been paramount.

Below are some "before and after" examples of reproduction tiles we have created:

6" x 6" Stabler reproduction tiles

for St John's Wood Station, London Underground

Reproduction sign for Covent Garden Station, London Underground

Website updates

We've been busy updating our website over the last month with more of our tiles and products - take a look at www.hesmith.co.uk

Thursday 20 June 2013

Hot off the press: designer tiles for Christian Louboutin Harrods store

Bespoke tiles produced by H&E Smith Ltd for designer Lee Broom are now in-situ at the newly opened Christian Louboutin store in Harrods, London.

The individual tiles, shown below, feature the luxury shoe designer's initials and a pair of his signature stilettos. A die was produced from Broom's design and used to create the tiles at H&E Smith's Stoke-on-Trent factory. The rich Bluebell and Burgundy glazes chosen for the scheme brought the tiles to life.

Images of the fully completed installation, plus further information about the project, can be found at the below links:

http://www.leebroom.com/news/lee-broom-designs-louboutin/

http://www.vogue.co.uk/news/2013/05/17/christian-louboutin-opens-standalone-harrods-space

The individual tiles, shown below, feature the luxury shoe designer's initials and a pair of his signature stilettos. A die was produced from Broom's design and used to create the tiles at H&E Smith's Stoke-on-Trent factory. The rich Bluebell and Burgundy glazes chosen for the scheme brought the tiles to life.

http://www.leebroom.com/news/lee-broom-designs-louboutin/

http://www.vogue.co.uk/news/2013/05/17/christian-louboutin-opens-standalone-harrods-space

Tuesday 7 May 2013

Showroom now open

H&E Smith are pleased to announce that their sister company, FireTile, now has a tile showroom open in Stoke-on-Trent, Staffordshire.

Here you will find the ceramic tiles manufactured at the H&E Smith factory, along with various other collections from carefully selected suppliers. We have an extensive range of products, from porcelain tiles and mosaics to the Westminster floor tile collection.

We also have a selection of home accessories on show, plus tools and adhesives in order to complete your tiling project.

The showroom is located at Britannic Works, Broom Street, Hanley, Stoke-on-Trent, ST1 2ER.

Our opening hours are 8.30am-4.30pm Monday to Friday, 10.00am-3.00pm Saturday.

If you have any queries or would like further information, please contact us on 01782 281617 or email info@hesmith.co.uk.

Here you will find the ceramic tiles manufactured at the H&E Smith factory, along with various other collections from carefully selected suppliers. We have an extensive range of products, from porcelain tiles and mosaics to the Westminster floor tile collection.

We also have a selection of home accessories on show, plus tools and adhesives in order to complete your tiling project.

The showroom is located at Britannic Works, Broom Street, Hanley, Stoke-on-Trent, ST1 2ER.

Our opening hours are 8.30am-4.30pm Monday to Friday, 10.00am-3.00pm Saturday.

If you have any queries or would like further information, please contact us on 01782 281617 or email info@hesmith.co.uk.

Subscribe to:

Posts (Atom)

.jpg)